DESIGN

3D Solid Modelling CAD

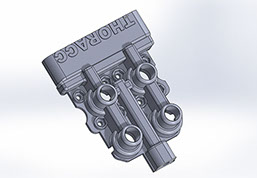

The industry standard software 'Solid Works' ensures that we quickly turn concepts into a screen image which can be sent directly to your computer for initial feedback. Once approved the drawings are instantly ready to prepare rapid prototypes or production tooling. Use of this system cuts costs and time,

Rapid Prototyping

We have recently invested in rapid prototyping technology to allow us to create actual models directly from Solid Works. Using this technology allows the customer to touch and feel a real product. Another benefit is that testing can start before any investment in tooling.

PCB Design

The PCB design is an integral part of most medical products, and we develop these in unison with the rest of the product using the most cost effective and reliable parts available on the market. There are numerous medical regulations controlling what can and cannot be used, and our vast experience enables us to design quick and reliable solutions. Once completed the initial samples are made in our own production facility.

Software Development

As the products are developed under a single roof the control software is written in unison with the design of the PCB circuitary. This helps cut time and costs and ensures a speedy, reliable end result which complies with the required medical regulations.

Medical Approval

A key factor in the devleopment of any new medical product is to have a full understanding of the medical standards. Throughout the product design this expert knowledge is utilised to ensure products are designed around these regulations from the start. This prevents expensive redesigns being required down line.

Intellectual Property

We can work with you to help protect your products' Intellectual Property. We have considerable experience in patent applications and can help you where required to ensure that costs are kept to a minimum by undertaking a lot of the ground work inhouse. In addition we can help identify patentable technology.

Pre-production Products

Being a fully approved medical engineering company,and using our own production facility, we have the ability to quickly produce small production runs of your new product to allow field trials and get your systems medically approved for sale.

With over 30 years of experience in designing and manufacturing medical devices MJS Healthcare has always focused on designing and building high quality products.

The numerous rules and regulations covering even the most basic elements, such as how to label your products, what level of traceability is required and even down to the colour of indicators is something that only a true understanding of the regulations can bring. Then you get to the complications of risk analysis and electrical safety testing all of which are unique to the medical sector. Without this integral knowledge of what is required for medical products, design costs can spiral out of control.

The experience and expertise which MJS Healthcare can offer you from the outset of a new project will help save you money and get your product to market in a timely manner. The use of our extensive in house facilities will play a major role in cutting both costs and time to market.

A dedicated project manager will be assigned to you individually so that you have a direct personal contact and help ensure that the project stays to the project plan which will be put together with you at the very beginning, along with a detailed breakdown of the expected costing. Whatever your company needs are MJS Healthcare have the ability to help.